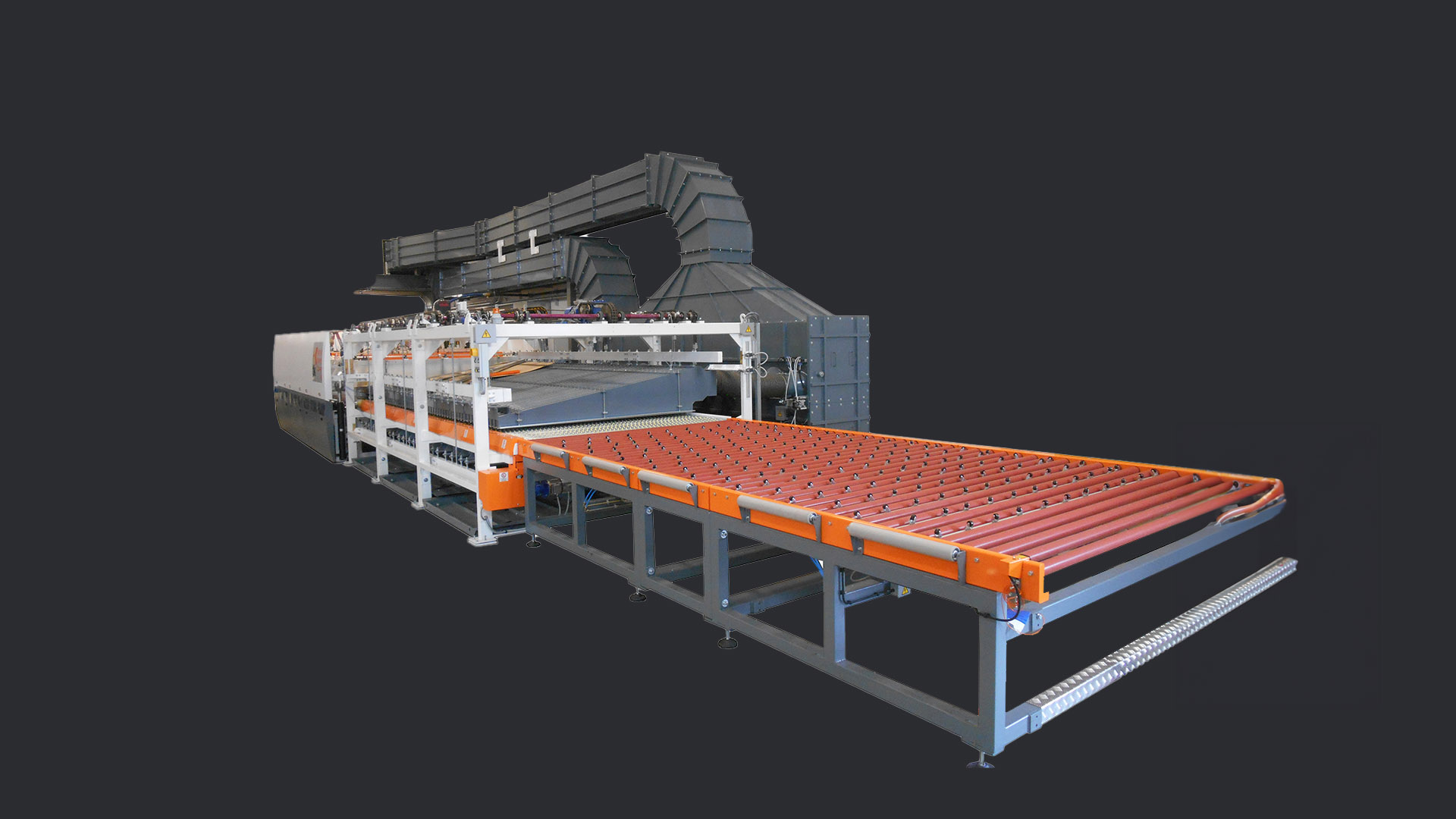

TK Master Temper

The non-plus-ultra of glass tempering ovens

Ideal hardening kiln to meet high production requirements

Master Temper oscillating kilns cover a size range to meet any production requirement, with glass sizes from 1300 to 3300 mm. The plants are equipped with all process control technologies in order to guarantee the highest quality at all times.

- Large dimensions

- High flexibility

- High production performance

Strengths

- Hot air convection directly in the heating chamber

- Hot air pre-heating chamber

- Fused silica ceramic rollers

- Movement of ceramic rollers with double belts

- Each individual zone has its own thermocouple connected to the control microprocessor, which in turn is interfaced with the process PLC

- Set-point, PID parameters, alarms and power percentage can be set for each zone

- All data are stored in the recipe and can be retrieved directly by the operator

- All data is password-protected

- The heating power is controlled by SCRs connected to the process PLC. Depending on the temperature trend inside the oven and the set management parameters, the SCRs modulate the output by sending more or less power to the heating elements

TK Master Temper: i vantaggi

Request a personalised consultation

Would you like more information or to talk to a TK specialist? Contact us and we will provide you with all the assistance you need to design the most suitable oven for your needs.

Discover our services

TKonnect 4.0

The TKonnect 4.0 remote system allows real-time monitoring of the TK ovens’ production process via smartphone or computer, combining a new, fully intuitive user interface concept with the latest technology available.

TKare

H24 remote technical support from our team, designed for your training; access to machinery from anywhere without the need for any software, data connection – downloading production reports via the Internet from any type of device.

TKlean Bag

The innovative laminating vacuum bag that avoids edge cleaning in any glass laminating oven: TK has introduced TKlean Bag, which, in combination with STRATO® interlayers, enables a perfect edge finish and improved glass flatness after the laminating process.