TK Extruders

Plastic polymer extrusion machinery

Innovative systems for processing raw materials into plastic components

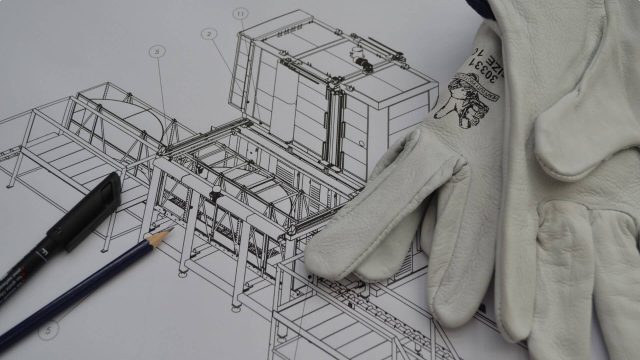

Extrusion is the transformation of polymer into a solid component through the action of two factors: heat and pressure.

The extrusion process begins with the hopper, into which the raw material is channelled for processing. The hopper is connected to a cylinder inside which the raw material is melted and processed to obtain the desired final shape.

Extrusion: what it is used for

This technology is used for almost all resins to obtain different types of artefacts.

Request a personalised consultation

Would you like more information or to talk to a TK specialist? Contact us and we will provide you with all the assistance you need to design the most suitable oven for your needs.

Discover our services

TKonnect 4.0

The TKonnect 4.0 remote system allows real-time monitoring of the TK ovens’ production process via smartphone or computer, combining a new, fully intuitive user interface concept with the latest technology available.

TKare

H24 remote technical support from our team, designed for your training; access to machinery from anywhere without the need for any software, data connection – downloading production reports via the Internet from any type of device.

TKlean Bag

The innovative laminating vacuum bag that avoids edge cleaning in any glass laminating oven: TK has introduced TKlean Bag, which, in combination with STRATO® interlayers, enables a perfect edge finish and improved glass flatness after the laminating process.