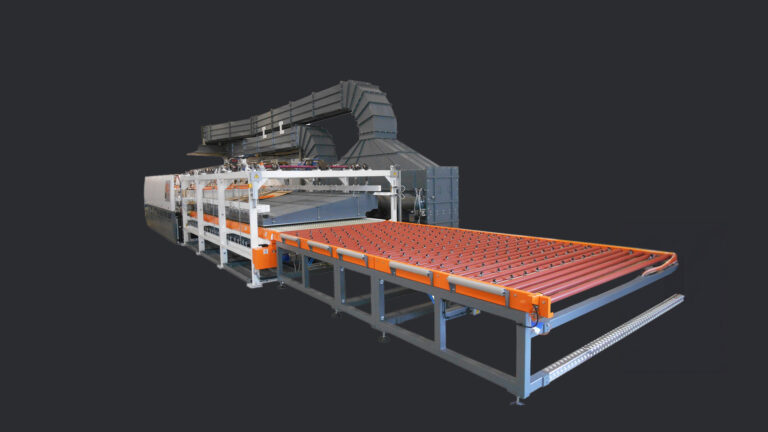

TK thermal tempering ovens

Glass anisotropy reduction kilns

Thermal tempering to ensure greater resistance of glass subjected to continuous stress

The Tempering or Thermal Quenching process is a treatment that heats the sheets to a temperature of approximately 650°-700°, quickly followed by forced cooling.

This treatment produces a process of crystalline reconstruction of the material, differentiating the surface structure from the internal structure. This makes the surface of the tempered glass sheet approximately 6 times more resistant to stress than float glass.

Furthermore, tempered glass panes crumble into small pieces in the event of an accident and breakage and do not give rise to sharp fragments that cause injuries and accidents.